Choosing the right Formwork

Choosing the right Formwork?

Today there are plenty of options when it comes to deciding which type of Formwork we need to, or want to use. Which is the best or the “right” Formwork?

The answer may be as simple as experience and knowledge gained from past projects.Before making a decision it may help to consider a few of the following more typical factors:

Personal Preference

- Many contractors choose a Formwork System that they are comfortable with.

They know from past experience that the equipment will assist them to achieve the results needed.

- The familiarity of more conventional type Formwork Systems may be considered as a way to reduce risk and exposure.

Building Geometry

- Forming to suit curves or angled geometry including any smaller areas might better suit the use of timber and ply, or the use of modular systems without panels.

- A combination* of systems may be more suitable – consider efficiency versus typical layout drawings.

* The combination might be conventional with timber and plywood and a modular system of choice.

Concrete Design and Specifications

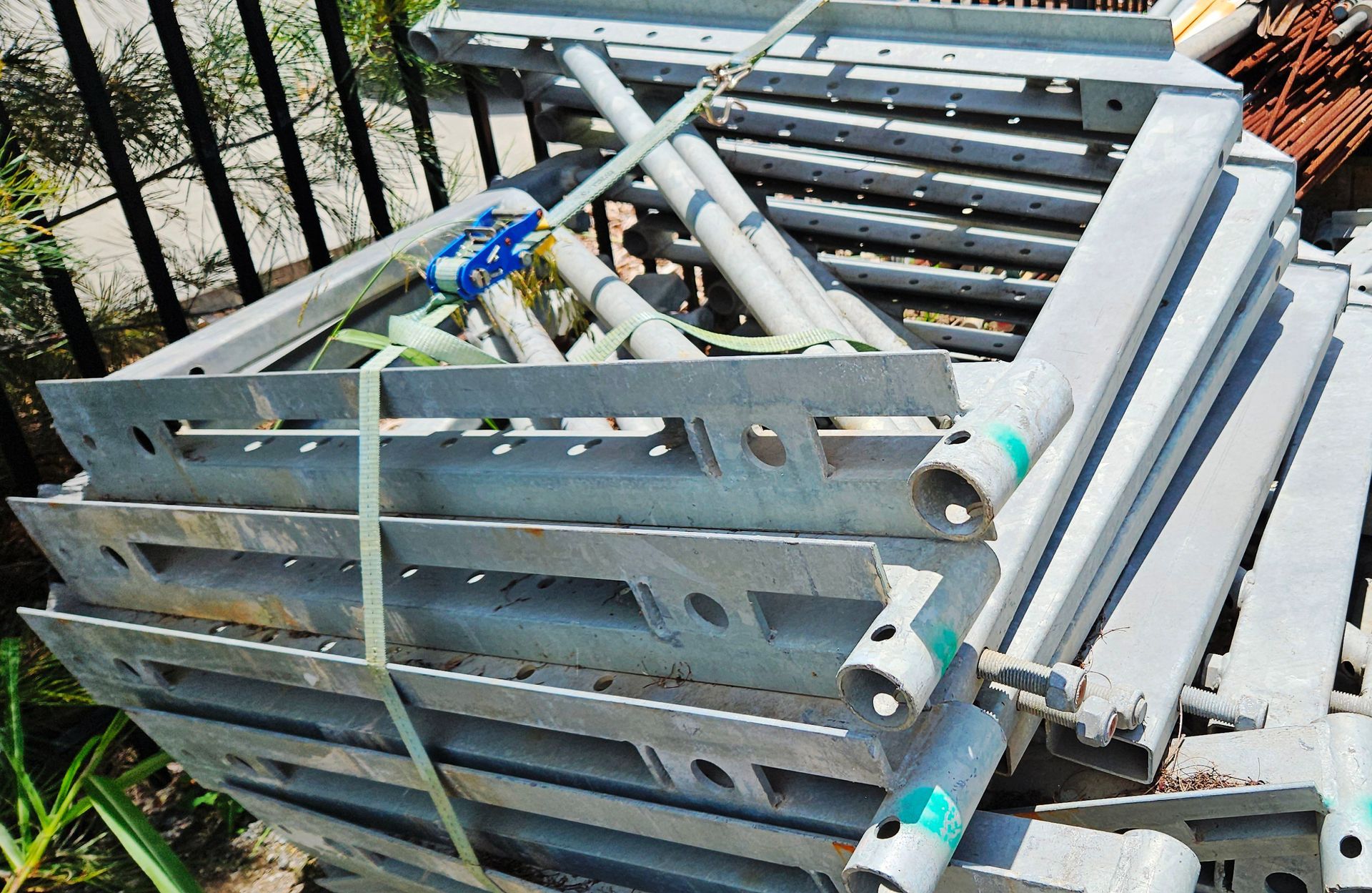

- Panel Systems are considered to be better suited for use when forming flatter RC slabs

- Grid or Secondary Systems can offer more versatility with infilling or make-ups around verticals.

- Achieving a Class 2 finish when using any type of Panel System may be difficult.

Program & Pour Cycle Time

- Many Modular Formwork Systems can assist the contractor to increase productivity with a reduction in man hours.

- A Modular Slab Formwork System with a Drop-Head feature typically reduces the amount of formwork needed on site. This can be achieved due to the possibility of stripping-out and reusing system components- including Main Beams, Secondary Beams and Panels.

- Lighter-Weight Modular Systems can be easier to move between floors or zones without a reliance on crane time.

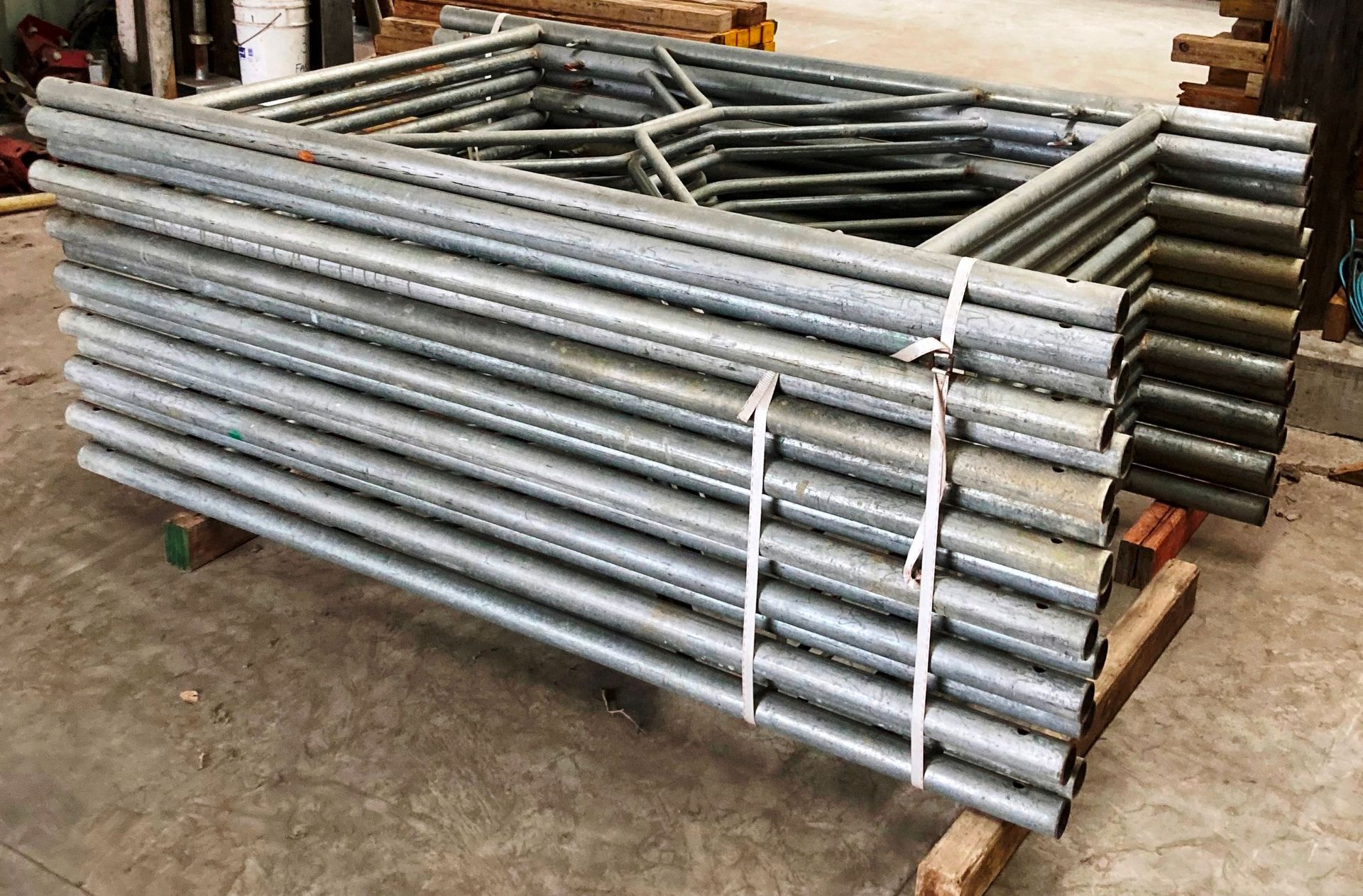

Availability and Cost Rental of Equipment

Consider:

- Delivery lead time

- Risk of construction delays and potential re-hire

- Impact on cash flow

Purchase

Consider:

- Payment terms and finance options

- Option to source locally or to import

- Delivery lead time